The company Deltrian, based in Fleurus, manufactures virucidal masks and air purifiers.

The CEO is focusing on innovation for this by offering a new range of virucidal masks and air purifiers dedicated to the catering industry.

Published on 02.04.2021

Table des matières

Decreased production

Innovations

James Amsens

Account Manager

That was a year ago, almost to the day. The Walloon government, desperate to no longer find any surgical mask on the world market, is calling on local companies to help. Deltrian receives the call five out of five and embarks on the adventure with almost no experience in the matter.

"We thought that with our expertise in filtration, we could probably help. And in the midst of a worldwide shortage of raw materials, we had the advantage of being able to rely on our own suppliers. We therefore responded to the call for tenders and our application was accepted. "

— Timothée De Greift, CEO of Deltrian International

"The machines were manufactured in Germany based on production methods developed in China. For once, it was the Europeans who were inspired by what we do there to produce it here. On June 5, we stamped our first surgical mask and we haven't stopped since. "

— Timothée De Greift, CEO of Deltrian International

Decreased production

The global shortage, the obligation to wear a mask and the need to offer quality equipment to healthcare personnel have helped Deltrian to develop its activity to produce up to 1.5 million masks per week. But today, if the epidemic is far from over, Asian countries have regained their grip on the market.

"We have reduced production to 1 million masks per week, adds the CEO. We have contracts that guarantee us production until mid-May, but after that it's the unknown. The only certainty is that in terms of price, we will not be able to compete with the Asian market. Even if our products are of a completely different quality, our masks are around 30% more expensive, which is not sustainable in the long term. But we are not giving up. On the contrary, we entered “survival mode” with a real hope of finding new outlets thanks to our innovations. "

— Timothée De Greift, CEO of Deltrian International

Innovations

Deltrian Protective Equipment aims to continue its fight against the coronavirus by offering high-tech products that meet a real need. Thus, the company began to produce masks < strong>virucides which offer additional protection, in particular by preventing transfer by hands and objects (pocket, bags, etc.) that come into contact with the mask.

"Thanks to a cold plasma technology, developed by our Luxembourg partner, NMPG, citric acid is projected in tiny quantities and serves as a barrier to the virus which comes to die there. Citric acid has the advantage of being virucidal and completely harmless to health and skin. "

— Timothée De Greift, CEO of Deltrian International

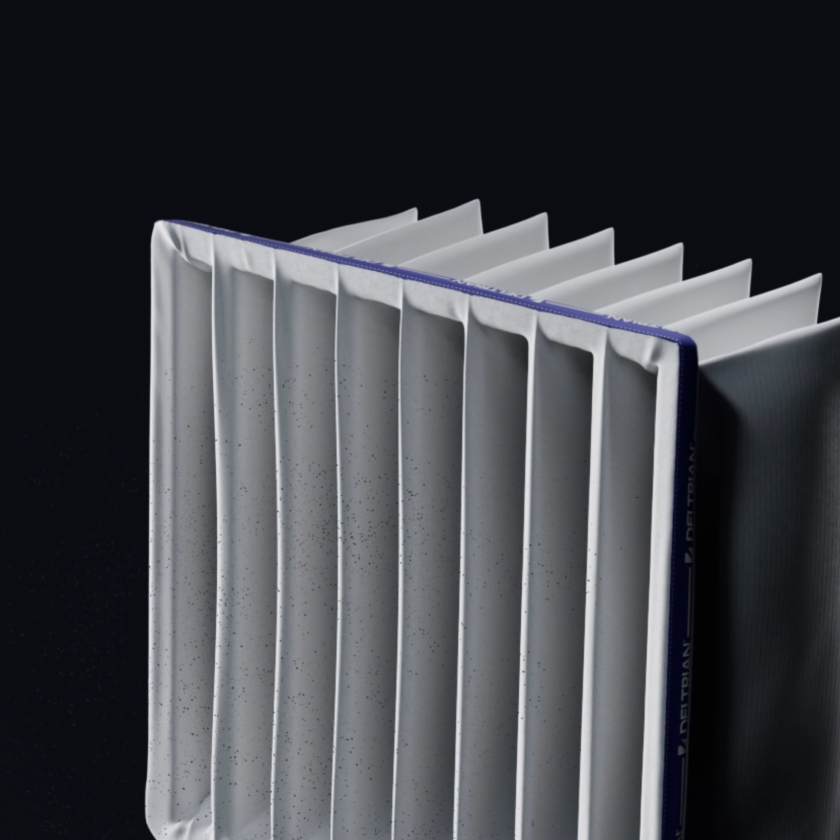

The company also sells more comfortable “citizen” masks and washable whose effectiveness increases with washing or even medical silicone mask intended more for the world of work. Finally, the latest innovation developed by the company brings it even closer to its core business: an air filtration device which, in a few minutes, decontaminates a 125 m2 room of fine particles but also of viruses.

"Other devices of the kind exist but ours simply plugs into a socket and due to its size, it can very well be placed in canteens or dining rooms. We also had a meeting recently with players in the horeca sector who showed interest in view of the deconfinement. "

— Timothée De Greift, CEO of Deltrian International

At 3,000 euros per filtration column, this will remain a significant cost for restaurants< /a> or the schools but Timothée De Grieft believes in it.

"We can never protect ourselves 100% from a virus, but our goal is to put as much barrier as possible between it and us. "

— Timothée De Greift, CEO of Deltrian International

James Amsens

Account Manager

Do you have questions? Our team is here to help you.

Our experts are at your disposal to answer all your questions.