Industrial molecular filtration: project for a major French manufacturer.

Deltrian designs and delivers a high-performance activated carbon filtration system for treating gaseous emissions at a production site belonging to a large industrial company in the Auvergne region.

Published on 22.01.2026

Table des matières

An exemplary project in molecular filtration

Pierre-Henry Martin

Sales Director for France, BELUX and French-speaking Switzerland

An exemplary project in molecular filtration

Deltrian is proud to share the results of a recent project that showcases our expertise in industrial molecular filtration: the design and supply of an activated carbon filtration system for treating gases emitted when production tanks are opened.

This project represents an in-depth technical collaboration aimed at resolving critical issues of air quality, operator safety, and regulatory compliance in a demanding industrial context.

The challenge: complex gas emissions to treat

The opening of production tanks generates complex and varied gas emissions, mainly comprising ammonia, volatile organic compounds (VOCs), formaldehyde, and traces of acids. These emissions present several major challenges for many industrial operators.

The issues to be resolved

Managing these emissions requires a rigorous technical approach to achieve several simultaneous objectives:

- Capture and neutralize pollutants before they are released into the atmosphere.

- Significantly reduce odor nuisance in the work area.

- Improve air quality and operator safety on site.

- Ensure regulatory compliance for channeled emissions.

The diversity of contaminants present (alkaline, acidic, and organic compounds) required a molecular filtration solution capable of effectively treating the entire spectrum of pollutants, while offering optimized service life and controlled maintenance.

Our solution: the Deltrian Deep Bed unit

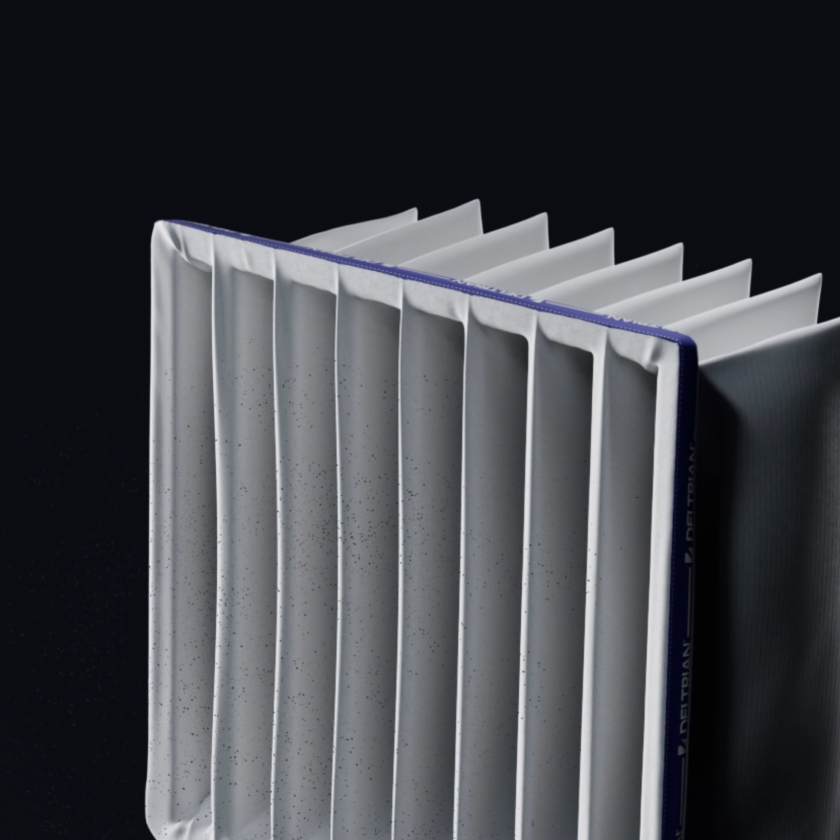

Faced with these technical challenges, Deltrian designed an activated carbon filtration system based on our Deep Bed technology, incorporating a strategic combination of three types of adsorbent and oxidizing media.

An innovative multi-media approach

The installed DDB unit incorporates a combination of three types of media, ensuring complete coverage of the targeted contaminants:

Non-impregnated activated carbon: dedicated to the adsorption of volatile organic compounds and odors thanks to its highly developed microporous structure.

Basic impregnated carbon: specifically formulated for the capture of alkaline gases such as ammonia and amines, offering chemical neutralization in addition to physical adsorption.

Permanganate-based oxidizing impregnated carbon: Designed for the neutralization of acidic and corrosive gases (H₂S, SO₂, NO₂, etc.) through chemical oxidation reaction.

Optimized technical sizing

The system design is based on precise sizing of the contact time between the gas flow and the filter media. This long contact time maximizes pollutant capture efficiency and significantly extends the life of the media, thereby optimizing the total cost of ownership.

Monitoring and predictive maintenance

To ensure optimal performance over time, periodic coal analyses are scheduled 3 and 6 months after commissioning. These analyses make it possible to assess the saturation level of the media and adjust the maintenance plan in a predictive manner, thus avoiding unplanned shutdowns.

The result: a high-performance solution!

Technical performance

The combination of the three types of media guarantees high abatement efficiency for all targeted pollutants. The appropriate contact time ensures optimized system life, reducing the frequency of maintenance interventions.

Operational benefits

The commissioning of the system has significantly reduced gas emissions and odors on site, directly improving air quality and the safety of operators working in the affected area. Regulatory compliance for channeled emissions is now guaranteed on an ongoing basis.

High-performance solution

The installed system meets the customer’s strict industrial requirements in terms of performance, reliability, and durability. This achievement provides a solid technical foundation for the development of similar future projects at other industrial sites facing comparable emissions issues.

Collective expertise

This success illustrates the strength of our collaborative approach and the expertise of our teams. The project was led by Costa Pironet, Lucas Villatte, Pierre-Henry Martin, and Nicolas Bustin, in close collaboration with our entire R&D team.

This collective effort made it possible to design a high-performance technical solution that is perfectly adapted to the specific constraints of the site and the performance objectives defined with the customer.

Contact us

Are you facing similar challenges in industrial molecular filtration? Would you like to learn more about our Deltrian Deep Bed solutions?

Our teams of experts are available to analyze your specific needs and design the right solution for your industrial constraints.

Pierre-Henry Martin

Sales Director for France, BELUX and French-speaking Switzerland

Do you have any questions? Our team is here to help.

Our experts are available to answer all your questions.